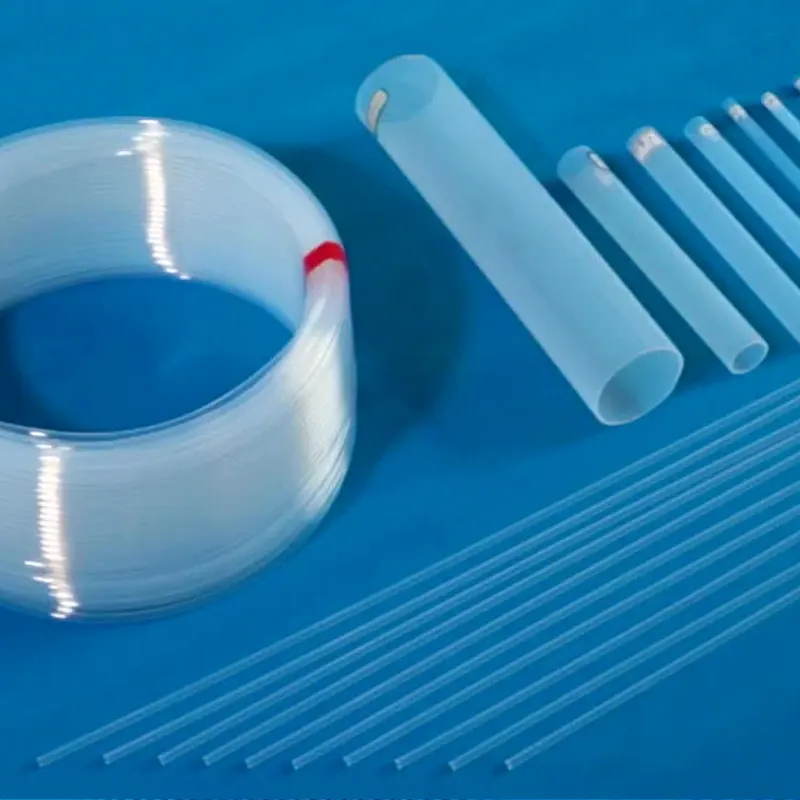

The quality of PFA (Perfluoroalkoxy) tubing plays a crucial role in ensuring the overall reliability of fluid handling systems in various ways:

- Chemical Resistance: PFA tubing exhibits exceptional resistance to a wide range of chemicals, solvents, and corrosive substances. This resistance prevents degradation or breakdown of the tubing when exposed to aggressive fluids, ensuring that the tubing remains intact and does not contaminate or compromise the integrity of the fluid being transported. This chemical resistance contributes to the long-term reliability of fluid handling systems, especially in industries where corrosive or reactive substances are handled.

- Temperature Stability: PFA tubing maintains its mechanical properties and dimensional stability over a wide temperature range, from cryogenic temperatures to elevated temperatures approaching 500°F (260°C). This temperature stability ensures that the tubing can withstand extreme operating conditions without deformation, cracking, or deterioration. As a result, fluid handling systems using PFA tubing can reliably transport fluids across a broad temperature spectrum, ensuring consistent performance in diverse environments.

- Low Extractable Content: PFA tubing has low extractable content, meaning it does not release harmful or contaminating substances into the fluid passing through it. This property is crucial for applications requiring high purity, such as pharmaceutical, biotechnology, and semiconductor manufacturing. By minimizing the risk of contamination, PFA tubing contributes to the reliability and integrity of fluid handling systems, China PFA Tubing suppliers ensuring the purity and quality of the transported fluids.

- Smooth Surface Finish: PFA tubing typically has a smooth inner surface finish, which reduces frictional resistance and minimizes fluid turbulence. This smooth surface finish promotes laminar flow, preventing the formation of deposits, scale, or biofilm inside the tubing. The absence of obstructions or irregularities ensures consistent fluid flow and prevents blockages or restrictions that could impede the operation of fluid handling systems, enhancing their reliability and efficiency.

- Flexibility and Durability: PFA tubing exhibits excellent flexibility and durability, allowing it to withstand bending, twisting, and repeated flexing without cracking or fatigue failure. This flexibility enables easy installation and routing of tubing within fluid handling systems, even in confined or complex configurations. The durability of PFA tubing ensures long-term reliability, reducing the likelihood of leaks, breaks, or system failures due to tubing damage or wear.

- Inertness and Biocompatibility: PFA tubing is inert and biocompatible, making it suitable for applications involving sensitive fluids or biological samples. The inert nature of PFA prevents interaction between the tubing material and the transported fluids, ensuring that the chemical composition and properties of the fluids remain unchanged. This inertness also eliminates the risk of leaching or contamination, contributing to the reliability and integrity of fluid handling systems in critical applications such as medical diagnostics, analytical instrumentation, and food processing.

Overall, the quality attributes of PFA tubing, including its chemical resistance, temperature stability, low extractable content, smooth surface finish, flexibility, durability, inertness, and biocompatibility, collectively contribute to the overall reliability of fluid handling systems. By ensuring consistent performance, purity, and integrity, PFA tubing helps maintain the efficiency, safety, and effectiveness of fluid transport in a wide range of industrial, scientific, and medical applications.